Pellet Sorter ||

Pellet Sorter ||

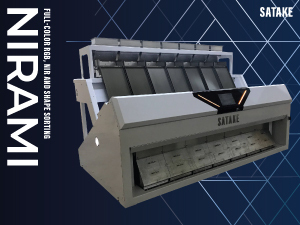

Satake USA has drawn on its extensive color sorting experience to develop the Pellet Sorter II, an optical sorter specifically designed to sort plastic pellets. Raw materials are fed at a carefully controlled rate to the conveyer belt, where a line of high resolution line scan cameras inspect each individual pellet. Signals from the cameras are amplified and processed to identify the targeted defects. Once identified, the objectionable pellets are removed from the acceptable stream with precise air blasts from the appropriate high speed air ejector.

Plastic pellets (diameter, nominally 3mm, cylindrical or hemispheric shape)

Black specks and discolored pellets from transparent, opaque and colored virgin pellets. Able to sort opaque to translucent white pellets from black pellets.

ELEVATE YOUR PRODUCT. PROTECT YOUR BRAND.

The new Satake Pellet Sorter II was designed with one goal in mind:

Uncompromising purity in every single pellet.

Whether you’re producing virgin or recycled material, the smallest defects can lead to costly rework, customer complaints, or even product recalls. With Satake’s advanced vision technology, you’ll detect and eliminate contamination before it ever becomes a problem.

KEY FEATURES THAT SET US APART:

- Ultra-High Resolution Detection: Sees what others miss – black specks, off-color pellets, cross-contamination, and more.

- High Throughput, Minimal Waste: Sorts up to 6,000 lbs/hr (depending on pellet density), maintaining extreme quality.

- Advanced sorting algorithms powered by advanced defect recognition delivering exceptional accuracy and improved efficiency.

- User-Friendly Interface: Intuitive controls and easy recipe recall. Quick changeovers. Minimal training required.

- Built to Last: Stainless steel contact surfaces, high frequency ejectors, and a clean design that stands up to harsh production environments.

- Engineered for ROI: Delivers value through reduced labor, improved quality, higher yields, and faster processing.

PUT IT TO THE TEST

Send us a sample. We’ll run it in our Houston Applications Lab and give you a full report-including photos, defect rates, and throughput data-so you can see exactly how it performs on your material.

SATAKE USA INC.

Trusted Worldwide. Delivered Locally.

With decades of experience in optical sorting, Satake continues to lead the way in precision-engineered solutions for the plastics industry.